New Articles

Best Sites to Purchase Domains

We already know that a website plays an important role. Even if it’s a big or small, it means a domain name. And nowadays it is increasing day by day and getting a perfect website is one of the crucial requirements. Now you can easily purchase your domain name through domain registrars as it is hard to know which site is best for registration to suit your needs as well as budget. As some of them are quite expensive and some of them are not having free features.

Domain.com

Domain.com was founded in 2000. An international endurance group owns it. This company is specialized for web hosting, VPS hosting, email, SSL certificates, domain names as well as for several online marketing services and web design. They have great hosting plans and WordPress hosting. No matter which plans you choose for yourself, you will also receive one free domain name along with the features. It also has excellent customer service, which is 24/7 phone support. You have to pay $9.99 every year.

GoDaddy.com

Bob Parsons founded in 1997. And it has been more than two decades. It was initially named as Jomax technologies. There are more than 17 million people who are using GoDaddy. It is one of the worlds largest domain name registrar. It holds more than 73 million domain names all around the globe. It gives you some features such as domain value approval, online marketing tools, web hosting, web security. In case if you feel to register, it will cost you around $15 each year.

Namecheap.com

Many adult dating apps are using .app domains for their sites. Other app companies look to follow suit and many .app domains are purchased on Namecheap. Namecheap was founded in 2000, which is based in Phoenix. It was founded by Richard, who has more than 3 million customers and more than 7 million domains. In November 2010 it was also awarded Best domain name registrar. It includes domain transfers, app integration, email and much more features. You can also have your private email hosting, said WordPress, reseller VPS. It will cost you around $8.88 per year.

Bluehost.com

Bluehost was founded in 2003. There are more than 2 million websites which are already posted with Bluehost. It adds on WordPress, VPS and also reseller hosting. Call customer support, and you will also have a live chat, Email ticketing. One domain name comes free with each hosting package if you are registering to this website you need to pay almost $12 for each year.

Name.com

Name.com was introduced in 2003 by William, which is the former president of Mushkin Inc. The right side group owns the company. It has gained more than three lakh customers from 2003, and now it has almost 17,000,000 domain names which are managed by the right side. It adds on the features such as domain transfers, SSL certificates and much more. In case if you want to register it, you need to pay $110 each year.

As we already know that registering and having our domain names has a lot of Advantages. The websites as mentioned above are sharing all web security, and you can easily promote your business.

How Do People Make Money Buying And Selling Domains?

Nowadays, purchasing and selling domain names seem to be an exciting adventure. And for some reason many find it to be like discovering a hidden treasure or guessing the winning lottery number of a Powerball. Of course, there are stories of individuals purchasing domains for $8 and then fifteen years later selling them for millions. So, it does make one wonder whether how it can be done.

Of course, it is a big sea and your chances of cashing in on the motherload are slightly low. Plus, you are liable to waste a lot of money and time chasing the wrong ship. It might be better if you have a map or someone to guide you to reach the desired booty so to speak.

Tips For Purchasing And Selling Domain Names For Profit

The following are some of the major tips you can follow to purchase or sell domain names for profits:

- Narrow The Focus

There are countless domains already registered by individuals and even endless combinations of an available domain for registration. Most importantly, hundreds of latest domain names extension popping up regularly like “.club” and “.app”.

In such cases, if you are planning on purchasing a domain and even reselling it, just begin by narrowing the focus. What are you aware of which can make this easier? For example, if you are well-versed about pets, then you could try getting a domain name like’ .dog’ or ‘.pet’ domain name.

In the same way, are you doing business related to home sales or car, then you might have to consider getting a domain name like ‘.realestate’ or ‘.car’ domain extension.

Also, if your profession is somehow related to healthcare or education, try to pick out domain names like ‘.education’ or ‘.doctor’. It is important you think about the things you are most familiar with and then begin the domain name search which can be based on your related keywords.

Once you have found out or narrow down your search, the next thing is to list out the things you must avoid. The first thing is to avoid targeting prospective buyers especially based on their economic status and without taking into account the insights related to the industry you are targeting.

You might feel that lawyers are doing well and assume that you can sell domains to them. So, you will go ahead and start purchasing domain names that might appeal to law firms, identifying them as potential buyers. Here you might not strike gold as the American Bar Association and other industry-specific industries present in certain countries have certain goals regarding the legal aspects of advertising.

So, understanding your audience will help your sales and even allow you to follow smoothly. You might keep a domain name for ten to fifteen years and still be able to sell it for a considerable amount of profit.

All you have to remember is that the focus must be on the areas you are very well aware of and that will help you to be successful in purchasing and selling the domains you think can be profitable for people in other industries. It helps to focus on particular niches. There are plenty of niches with varying levels of competition and profits to be had. Many people choose to focus on the adult website niche and piggy back off of larger brand names. For example and adult site like LocalSexfinder.com might bring value to the domain name local sexfinder followed by any other popular extension. Another strategy in this niche is domain names that maintain the .com, but partial match such was with bedpage and backpage.com

- Try To Get Names Providing Real Value

You must always think of the domain as a valuable asset that the buyer wants. Just picture a person who might benefit from purchasing your domain in the space you are best in. If you were in the buyer’s place and someone was trying to sell you this particular domain name, can be it be beneficial for you if you owned it? Just be honest, and if it is then why and if not, why.

Just utilize these answers to refine your search for the best domain names.

- Gather More Detail About Domain Availability

Finally, you have narrowed down to what name you might be going to buy, then you must think about how you are going to find them. Here, the first thing you must do is check out if the names are available for purchase as new registrations.

If the names are taken (most probably most of them will be), just go to the aftermarket for purchasing from people who own these names or you allowed them to expire just because they plan on not using them.

By using your advanced search options you can quickly hone on the kind of names you are interested in. Then try to narrow down your results based on the price, top-level domain, keywords, etc.

Making Income Through Purchasing & Selling Domain Names

Certain people are making a living by purchasing and selling domains. If you can purchase a web address having business names, generic names, geographical names, or some popular names, then you can easily sell them at a decent and good price.

Most of the companies and individuals are often interested in generic names. So, if you are able to find one, then go ahead and purchase them at a few dollars each. Later on, you can sell them for a few hundred or even thousands.

What Is A Domain?

Looking to build and create your own website? In order to run it successfully online, you need to choose a domain name that is vital for anyone who wants to rule the web development industry to niche his new website. Before you get ready to register for a domain, you need to acquire a strong know how about what is a domain? How it works and what are its different types in order to pick the best domain name to suit your business. For example, as everyone has an address likewise every domain has its physical address that is visible online on the World Wide Web. As the house address or GPS allows the individuals to trace the location of a particular house similarly, a domain navigates web browsers to land on the right website they are looking for, which is actually the face of your brand or website. Hence, the domain gives you access to perform all user functionalities through user credentials and authentication of shared system resources.

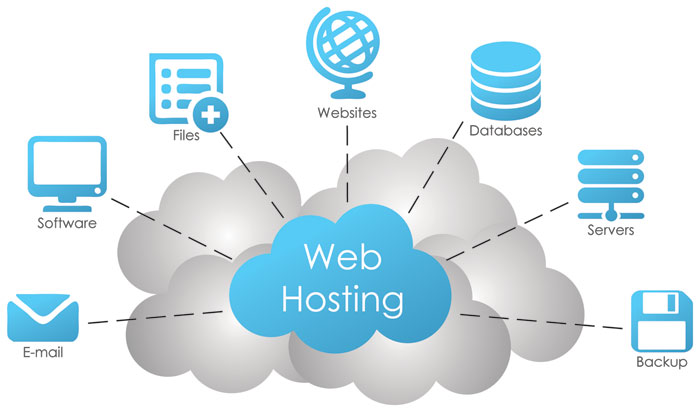

How does a domain work with web hosts?

As said above domain plays a vital role to make your business or website successful on the internet. A good domain name works as your brand’s first impression. Some of the popular domains include Google.com, Facebook.com, Amazon.com, and many more. Therefore when clicked on the domain name it helps visitors to find the right website in a faster manner with the help of search engines. Hence domains are easy to remember when written in short than the complicated IP addresses which need to be entered into the browser address bar to find the information needed.

When anyone is looking to access a domain name to build and create their own website this organization specifies them available names and extensions to the owner that are easy to use. This organization possesses a huge database and the DNS, domain name system, gives you access to the right website that has user-friendly domain name and stores all the website essentials at one place otherwise rent a hosting company that ensures high-quality with search engine ranking to search particular website online.

Different Types of Domains Available Online:

Now that you got an idea of what domain names are and how they work on the cloud, let’s get into detail to learn different types of domain names available in the server to register your name.

There are multiple types of extensions available in the server that meets true to your website content. Basically, there are five different types of domains available let’s check them in detail below:

- Top-Level Domains

They are always on the top of the internet hierarchy with respect to domain names which are commonly referred to as TLDs. However, there are over thousands of different TLDs that ICANN opened in recent years. The TLDs that are currently available to register your domain name are: .com, .info, .website, .net, .org, .co, .site, .online, .host, .me, .club and a few more.

- Country Code Top Level Domains

They are actually technically associated with different countries and every country has its own country code top-level domains (ccTLD). For example, if the website or company belongs to Colombia then the domain extension is visible as .co, for Japan it is .jp, for the US it will be .us and so on linked according to the country.

- Generic Top-Level Domains

Generic top-level domains (gTLDs) are just a variation of TLD. The generic domain refers to the types of use-cases used to design a domain name for example; there are few educational institutions that are accessible with .edu and .org that is actually a nonprofit organization. Anyone can easily access this domain to register even if they don’t furnish proper details, but the website content needs to fit exactly to the requirements.

- Second-Level Domains

Though they are known as second-level TLDs they are a bit low in the hierarchy. But that doesn’t mean they are not valuable or authorized. Thus the second-level domain names are linked with country codes that appear as:

.co.uk-for companies functional in United Kingdom

.gov.uk-for government agencies in the United Kingdom

.gov.au –for government agencies in Australia

- Third Level Domains

Third level domains come after second-level domains and listed below in the hierarchy. They aren’t a full domain name in and of themselves, but merely a portion of a domain name. You can also access the subdomain to build an additional part of your site which will be known as a third-level domain. Leverage these types of the domain to add one more blog to your website, build and create a resource section, host an app, or access it to create an online store.

Tips to Choose Right Type of Domain Name:

Now that you got an idea about different types of domain names available in the web industry, let’s check how you can choose the best domain name that meets your specific needs with the right kind of extension when looking to create your own website or blog.

Here’s how you can choose the right domain name with extension:

- From the wide varieties of domain name extensions available to choose from make sure your chosen domain and extension cater to different types of websites. It should align with your topic and help you meet your website goals.

- The one who is looking for TLDs which are commonly used domains then you have got a plethora of options to deep dive. It is ideal to choose a unique extension and go for something that is common like .com, .org, .net, etc. However, if you are willing to pick the extensions choose something different which will migrate your website to a new extension in order to maintain your existing audience.

- As said there is a variety of domains the most common is .com that is widely accepted and easy to register. Once you had established your website domain later forward all your extensions to your primary domain which is easy to manage and helps your dream come true. Access the list of potential options to stay ahead of your competitors.

Conclusion:

Are you ready to choose a domain? I hope the above information is true to satisfy all your domain requirements. It is a fact that choosing the right kind of domain is highly essential as it is the face of your website and helps build your brand around. Domains not only improve your chances of success but its extensions also keep you going to complete your project altogether to get accessible online!